thermal treatment

Thermal-treatment offers the means to transform organic materials into value-added “engineered biocarbon” for various sustainable applications such as bioenergy, biofuels, biomaterials, sustainable agriculture, etc.

Omega Thermal Solutions Group offers a variety of options for thermal processing and is a leader in the innovation of future system designs.

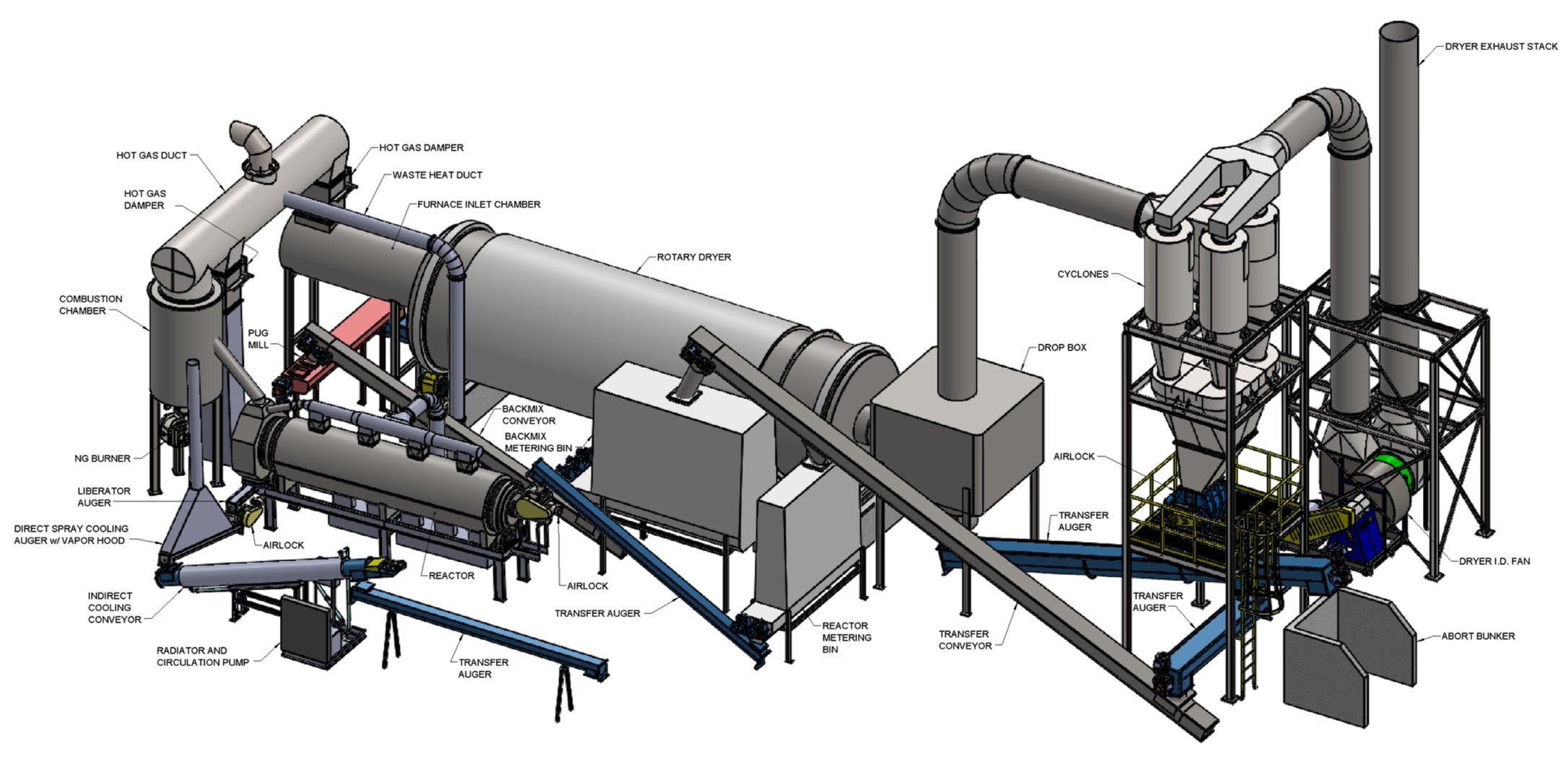

Biocarbon Flow Process

Omega developed a versatile and reliable pyrolysis system to transform organic feedstocks into engineered products for valued-added applications.

Patented, pyrolysis system

Variable processing temperature for tailored properties

Variable retention time

Oxygen-starved condition inside reactor to prevent ignition.

Waste Heat Recovery for onsite process

VOC Combustion and heat recovery

Pyrolyzed product cooling and transfer

Utilized multiple sources of thermal energy

Processing rate ranging from 200pph to 50,000pph feed rate

BIOCarbon SYSTEM

THERMAL TREATMENT TECHNOLOGY

ROTARY DRUM REACTOR

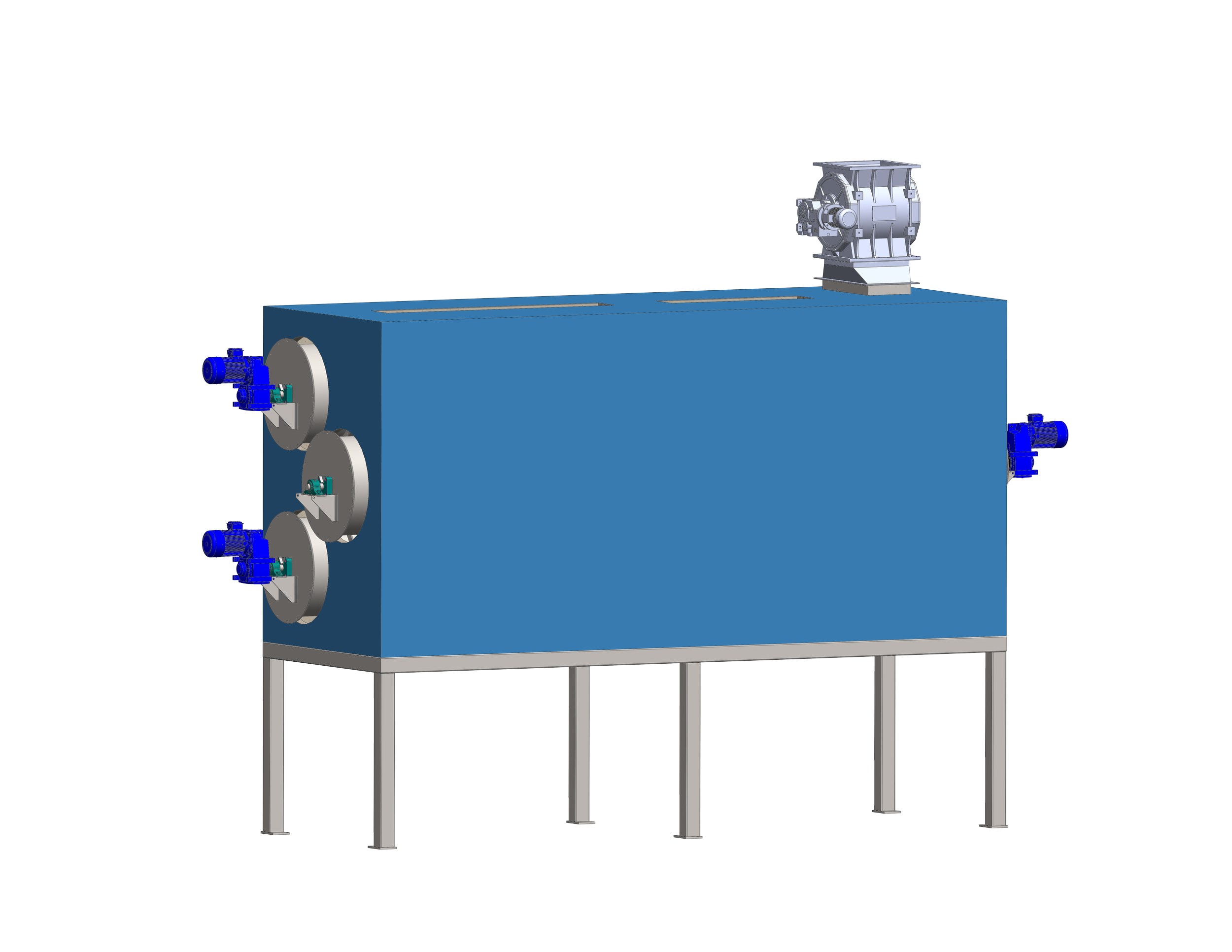

SCREW REACTOR

Applications for Thermal Treatment

BIOENERGY

Renewable power and energy

Hydrophobic, friable and high calorific value

Drop-in Fuel Replacement for coal and pet coke

Ready availability unlike wind and solar

Lower emissions of N, S and toxic heavy metals

Fuel in power plants and cement kilns

Gasification

Odorless and biologically stable feedstock

Increased chemical efficiency for gasification

Production of renewable diesel and jet fuel

Production of renewable hydrogen

High cetane number

Low Sulphur emissions and soot formation

Sustainable ag

Increase soil fertility

Increase moisture and nutrient retention

Increase soil ion exchange capacity

Enhance growth of soil microbiome

Immobilize heavy metals

Increase soil tilth

biomaterials

Engineered fillers for polymer composites

Engineered source for graphene production

Application for construction materials

Application for nanotechnology

Application for water and gas purification

Application for soil remediation